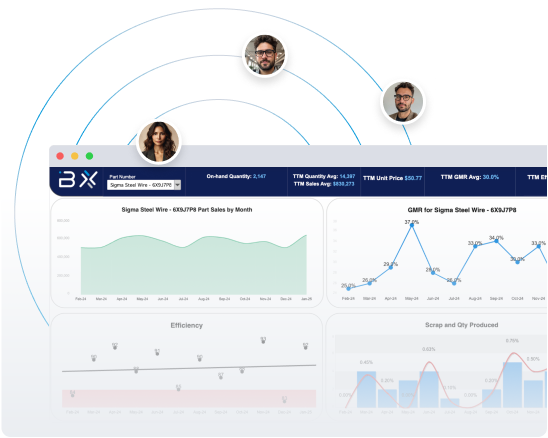

Visualize Your Manufacturing Data Like Never Before

Stop struggling with scattered reports and manual spreadsheets. Bearex connects your systems, analyzes key metrics, and delivers clear insights – so you can spot inefficiencies, improve production, and make data-driven decisions without the hassle of manual reporting.

The Bearex Process Explained

How We Turn Disparate Data Into Powerful Insights

Powerful Features Backed by Manufacturing Expertise

Bearex is part SaaS, part consulting platform that unifies ERP, machine sensors, and financial data into live analytics. From shop floor to C-suite, we help you drive efficiency, maximize profits, and stay ahead of market demands.

Experience Smarter Manufacturing with Bearex

Seamlessly connect data, optimize operations, and get deeper insights with solutions that improve every aspect of your manufacturing operations.

End-to-End Supply Chain Intelligence

Gain instant visibility into shipments, inventory, and supplier performance to optimize logistics and mitigate risks.

Customizable Manufacturing Dashboards

Visualize key metrics with interactive manufacturing KPI dashboards tailored to your business needs.

Manufacturing Data Integration Solutions

Connect ERP, machine data, and financials into one seamless manufacturing data integration platform.

Production Scheduling Optimization

Automate production scheduling, reduce downtime, and ensure machines, labor, and materials are used efficiently to meet demand.

Data-Driven Decision Support for Manufacturing

Transform raw manufacturing data into real-time insights with Bearex, helping you optimize operations, reduce waste, and increase profitability.

Labor Productivity Analysis

Measure manufacturing employee efficiency, track performance trends, and identify areas for improvement within your workplace.

Unified Manufacturing Data Platform

Integrate ERP, machine data, and financials into one connected system for live, end-to-end operational insights.

Real-Time Supply Chain Analytics

Use the CFO Scorecard to analyze 12 months of sales, net income trends, and cost drivers for data-driven financial decisions.

ERP Analytics Solutions

Get enhanced ERP data with custom, current analytics, eliminating the burden of overanalyzing rigid reports.

Custom Report Generation for ERP

Eliminate manual work with Bearex’s automated ERP reporting, delivering customized insights for your business needs.

Manufacturing KPI Tracking

Track, analyze, and optimize key performance indicators in real-time to drive productivity and cost savings.

Manufacturing Analytics Software

Turn complex production data into actionable insights, helping you boost efficiency, reduce waste, and anticipate market shifts.

Get Smarter Manufacturing in Three Simple Steps

Our process includes transforming ERP reports, machine logs, and financials into a customizable manufacturing dashboard, providing clear insights to track efficiency, reduce downtime, and optimize production without manual work.

“We see all our most important

measurables in one place, with the ability for analysis to drive

accountability”

Step 1

Discovery

We start by analyzing your manufacturing data integration needs and identifying blind spots in manufacturing employee efficiency, production meetings, and headcount data to uncover areas impacting profitability.

Step 2

Deployment

Bearex integrates with your existing systems, eliminating manual manufacturing headcount data tracking and simplifying manufacturing parts grading. This step ensures you get immediate insights without disrupting operations.

Step 3

Scale with Support

With manufacturing by part view and production tracking, Bearex continuously optimizes your data, improving efficiency while our team provides ongoing support to enhance decision-making and operational performance.

Frequently Asked Questions

1. How does Bearex improve ERP analytics for manufacturers?

Bearex enhances ERP analytics solutions by transforming raw ERP data into custom, live insights that help manufacturers track efficiency, minimize waste, and optimize production without manual spreadsheet work.

2. What types of data can Bearex integrate?

Bearex connects ERP, machine data, financials, production logs, and supply chain information into a unified manufacturing data platform, providing visibility across all operations.

3. How does Bearex help with labor productivity analysis?

Bearex tracks manufacturing employee efficiency, measuring labor performance, identifying inefficiencies, and providing actionable insights to improve productivity and reduce downtime.

4. Can Bearex generate custom reports for ERP systems?

Yes, Bearex offers custom report generation for ERP, eliminating rigid, one-size-fits-all reports by providing tailored, automated financial and operational insights.

5. What are the key benefits of using Bearex for manufacturing data integration?

Bearex automates manufacturing data integration, eliminating manual exports, connecting systems, and delivering clear, real-time analytics for smarter decision-making and higher profitability.